|

Emergency Shut-Off Safety Valves

Industries Applications

Storage Tank Facilities

Offshore Drilling and Production Platforms

Oil/Petrochemical Refineries

Chemical Processing Plants

Pulp and Paper Plants

Pharmaceutical Manufacturing Facilities

Natural Gas Supply Lines

Sewage Treatment

Marine Loading Systems

Rail Loading Terminals

Truck Loading Terminals

Barge Loading Terminals

Barge Transportation

|

|

|

|

|

|

Feature and Performance Advantage

-

Positive shut-off - fail safe closure prevents the flammable product from

feeding the fire.

-

High capacity - 100% flow throught the valve, excellent pressure drop to flow.

-

No hydraulic shock - controls speed of closing. Does not slam.

-

Tamper proof - installed inside the tank or pipeline preventing unauthorized

tampering with valve actuators.

-

Always ready to perform - unaffected by power failure, easily installed in

remote locations.

Standards and Acceptance

-

Underwriter Laboratories.

-

United States Coast Guard.

-

National Fire Protection. Section 2343, pamphlet 58.

|

|

|

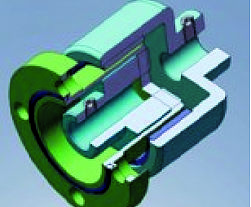

The SchuF Group designs and manufactures industrial valves that

control, isolate, divert, or sample gases, liquids, slurries or

powders. Our range of industrial valves are ideal for difficult

or severe service conditions found in the chemical,

petrochemical, polymer, oil, gas, refining and offshore

industries.

|

304 Series: Three Way, Two

Position, Low Pressure Valves

|

550 Series: Back Pressure,

Low Pressure Valves

|

|

Low pressure valve for diverting,

blending and metering

Working Pressure –

600 psig in 2”, 300 psig in 3” and 4”

Ductile iron body; variety of trim and

internal materials

Soft trim for bubble tight shut-off

Readily fitted for Electric/Hydraulic

actuator

Ideal for metering skids, test

manifolds and other diverting operations

|

Maintains upstream pressure within a

preset range

Working Pressure – 100 to 350 psig in

2”; 90 to 300 psig in 3”; 50 to 200 psig in 4”

Self contained back pressure operation

or use Pathway R2800 pressure pilot

Ductile iron body; variety of trim and

internal materials

Soft trim for bubble tight shut-off

Excellent for separator back pressure

relief or a custody transfer dump valve

|

|

500 Series: Two Way, Low

Pressure Valves

|

8100 Series: Two Way, High

Pressure Valves

|

|

On-off or modulating control on low

pressure applications

Working Pressure – 600 psig in 1”, 2”

and 3”; 300 psig in 4”

Ductile iron body; variety of trim and

internal materials

Excellent low pressure dump valve for

oil & gas separators, heaters/treaters or other liquid

accumulators

|

On-off or Throttling Control on high

pressure applications

Working Pressure – 6000 psig in 1”;

3000 psig in 2”

Cast steel body; variety of snap acting

and throttling trim sets and internal materials

Excellent high pressure ‘dump valve’

for oil & gas separators, gas scrubbers and other liquid

accumulators

|

|

D175 Series: Two Way, High

Pressure, No Freeze Valves

|

8900 Series: Two Way,

Overbalanced Valves

|

|

Economical snap acting no freeze valves

Working Pressure – 2160 psig

1” MNPT Inlet & 3/4” FNPT Outlet

Steel or 316 Stainless steel body, 440C

Stainless steel standard trim

Excellent for oil & gas separators, gas

scrubbers and other liquid accumulators

|

Used for bubble tight shut-off on high

differential pressures

Working Pressure – 1500 psig in 1” and

2”

Cast steel or 2” Stainless steel body;

variety of trim and internal materials

Excellent for shutting in oil & gas

wells; replaces double ported valves

|

|

8500 Series: Three Way, Two

Position, High Pressure Valves

|

400 Series: Two Way,

No-Freeze Valve and Angle Valves

|

|

High pressure valve for diverting,

blending and metering

Working Pressure – 6000 psig in 1”;

3000 psig in 2”

Cast steel or 2” Stainless steel body;

variety of trim and internal materials

Excellent for well test manifolds,

metering skids and other diverting operations

|

On-off or throttling controls in high

pressure applications

Working Pressure – 4000 psig in 1” FNPT

inlet & outlet; 4000 psig in 2” MNPT vessel &1” FNPT

outlet; 1500 psig 1” MNPT inlet & 1” FNPT outlet

Steel or Stainless steel body; variety

of trim and internal materials

Used for oil & gas separators, gas

scrubbers and other liquid accumulators

|

|

8950 Series: Back Pressure

or Pressure Reducing, Overbalanced Valves

|

8150 Series: Back Pressure

or Pressure Reducing, High Pressure Valves

|

|

Maintains a constant pressure upstream

or downstream

Working Pressure – 1500 psig in 1” and

2”

Cast steel or 2” Stainless steel body;

variety of trim and internal materials

Excellent to maintain pressure on

separators & other vessels and for pressure reducing on

gas lift operations and protecting downstream equipment

|

Maintains a constant pressure upstream

or downstream

Working Pressure – 6000 psig in 1”;

3000 psig in 2”

Cast steel body; variety of trim and

internal materials

Excellent to maintain pressure on

separators & other vessels and for pressure reducing to

protect downstream equipment

|

|

410 Series: Three Way, Two

Position, High Pressure, Balanced Valves

|

R2800 Series: Pressure

Pilots

|

|

High pressure valve for diverting,

blending and metering

Working Pressure – 1500 psig to 3000

psig in 2”

Cast steel or stainless steel body;

variety of trim and internal materials

Excellent where large differential

pressures are involved

|

Non-bleed reverse acting pilots

Signal pressure – 25 psig to 350 psig

Supply pressure – 5 psig to 50 psig,

air or gas

Cast iron and aluminum materials; some

components available in stainless steel

Used to throttle control valves for

constant field adjustable pressure setting

|

|

884 & 992 Series: Valve

Position Indicators

|

|

|

Use to actuate a switch when a valve

opens or closes

885 uses two SPDT micro switches; cast

iron body

992 uses two SPST reed switches;

stainless steel body

|

|

Pathway Liquid Level Controls

Click Image for PDF

|

E200 Series: Electric Level

Control Switches

|

P120 Series: Snap Acting

Non-Bleed Pneumatic Level Controls

|

|

Float-actuated switches for high/low

level control and interface control

Working Pressure – 1500 psig to 5000

psig max

Low specific gravity .4 and above

316 SS wetted components

Hermetically sealed switch cartridge

Single seal application approved

1 1/2" NPT, 2” NPT or flanged

connection

Certification – CSA: Class 1, Div. 1,

Groups A,B,C,D; Class II, Div 1, Groups E,F,G; Class

III, Div. 1 to USA & Canada standards

|

Float-actuated pneumatic switch for

high/low level control or to operate control valves

Working Pressure – 1500 psig to 5000

psig max

Snap acting non-bleed from 0 to full

supply

Low specific gravity .5 and above

316 SS wetted components

No internal seal used thus eliminating

the possibility of process fluid leakage

2” NPT standard, available 1 1/2“ NPT

or flanged connection

|

|

E200 Series – Manual

Override Electric Level Control Switches

|

P120 Series – Manual

Override Snap Acting Non-Bleed Pneumatic Level Controls

|

|

E200 control with manual override for

ease of field testing

Working Pressure – 1500 psig max

Low specific gravity .4 and above

316 SS wetted components

Hermetically sealed switch cartridge

Single seal application approved

1 1/2" NPT, 2” NPT or flanged

connection

Certification – CSA: Class 1, Div. 1,

Groups A,B,C,D; Class II, Div 1, Groups E,F,G; Class

III, Div. 1 to USA & Canada standards

|

P120 control with manual override for

ease of field testing

Working Pressure – 1500 psig max

Snap acting non-bleed from 0 to full

supply

Low specific gravity .5 and above

316 SS wetted components

2” NPT or flanged connection

|

|

E200 Series – Extended Body

Electric Level Control Switches

|

P120 Series – Extended Body

Snap Acting Non-Bleed Pneumatic Level Controls

|

|

E200 control with extended body for

increased reach inside vessel

Working Pressure – 5000 psig max; 1500

psig with manual override

Low specific gravity of .5 and above

316 SS wetted components

Hermetically sealed switch cartridge

Single seal application approved

2” NPT or flanged connection

Certification – CSA: Class 1, Div. 1,

Groups A,B,C,D; Class II, Div 1, Groups E,F,G; Class

III, Div. 1 to USA & Canada standards

|

P120 control with extended body for

increased reach inside vessel

Working Pressure –5000 psig max; 1500

psig with manual override

Snap acting non-bleed from 0 to full

supply

Low specific gravity .5 and above

316 SS wetted components

No internal seal used thus eliminating

the possibility of process fluid leakage

2” NPT or flanged connection

|

|

E200NF Series: Electric

Flow Indicator

|

P120NF Series: Pneumatic

Flow Indicator

|

|

Paddle operated electric indicator of

liquid or gas flow

Working Pressure – 5000 psig max

Variety of paddle lengths

316 SS wetted components

Hermetically sealed switch cartridge

Single seal application approved

1 1/2" NPT, 2” NPT or flanged

connection

Certification – CSA: Class 1, Div. 1,

Groups A,B,C,D; Class II, Div 1, Groups E,F,G; Class

III, Div. 1 to USA & Canada standards

|

Pneumatic paddle operated indicator of

liquid or gas flow or no flow

Working Pressure – 5000 psig max

Variety of paddle lengths

316 SS wetted components

No internal seal used thus eliminating

the possibility of process fluid leakage

2” NPT standard, available 1 1/2" NPT

or flanged connection

|

|

EV200 Series: Electric

Vertical Level Control Switches

|

PT100 Series: Throttling

Pneumatic Level Controls

|

|

Float-actuated vertical switch for

high/low level controls

Working Pressure – 250 psig max

Low specific gravity .7 and above

316 SS wetted components

Hermetically sealed switch cartridge

Single seal application approved

1 1/2" NPT, 2” NPT or flanged

connection

Certification – CSA: Class 1, Div. 1,

Groups A,B,C,D; Class II, Div 1, Groups E,F,G; Class

III, Div. 1 to USA & Canada standards

|

Float actuated throttling pneumatic

level device for high/low level control or to operate

control valves

Working Pressure –

1500 psig to 5000 psig max

Throttling output 3 – 15 psig with 20

psig supply

Low specific gravity of .4 and above

316 SS wetted components

No internal seal used thus eliminating

the possibility of process fluid leakage

2” NPT or flanged connection

|

|

C300 Series: External Cage

for Level Controls

|

C303 Series: External Cage

for Level Controls

|

|

Use in applications where level

controls are contained outside the vessel

Working Pressure 5000 psig max (3000

psig on ring bolted)

Choice of materials for use with most

liquids or liquid interfaces

Ductile iron – C300

Carbon steel – C300CS

Stainless steel – C300SS

Control connections 1 1/2“ NPT, 2” NPT

or ring bolt flange

Process connections 1” NPT, 1 1/2” NPT,

2” NPT; socket weld connections of 1”, 1 1/2" and 2” on

the C300CS and C300SS

S100 sight glass available for visual

inspection

|

Use in applications where level

controls are contained outside the vessel

Working Pressure 2500 psig max

Choice of materials for use with most

liquids or liquid interfaces

Carbon steel – C303CS

Stainless steel – C303SS

Control connections 1 1/2“ NPT, 2” NPT

or ring bolt flange

Process connections 1” NPT, 1 1/2” NPT,

2” NPT; socket weld connections 1”, 1 1/2", 2”

S100 sight glass available for visual

inspection

|

|

S100 Series: Sight Glass

|

P110 Series: Snap Acting

Pneumatic Level Controls

|

|

Provides visual indication on level

controls or safety systems

Use with Pathway C300 and C303 Series

external cages

|

Float-actuated pneumatic switch for

high/low level control or to operate control valves

Working Pressure – 1500 psig to 5000

psig max

Snap acting from 0 to full supply

Low specific gravity .4 and above

316 SS wetted components

No internal seal used thus eliminating

the possibility of process fluid leakage

2” NPT or flanged connection

|

|

PT101 Series – Extended

Body Throttling Pneumatic Level Controls

|

P111 Series: Snap Acting

Pneumatic Level Controls

|

|

PT100 control with extended body for

increased reach inside vessel

Working Pressure – 1500 psig to 2500

psig max

Throttling output 3 – 15 psig with 20

psig supply

Low specific gravity of .4 and above

316 SS wetted components

No internal seal used thus eliminating

the possibility of process fluid leakage

2” NPT or flanged connection

|

P110 control with extended body for

increased reach inside vessel

Working Pressure – 1500 psig to 2500

psig max

Snap acting from 0 to full supply

Low specific gravity .4 and above

316 SS wetted components

No internal seal used thus eliminating

the possibility of process fluid leakage

2” NPT or flanged connection

|

|

6100 Series: Static Head

Pressure Switches & Vapor Pressure Switches

|

22262 Cuttler Road • New

Caney, TX 77357

Phone (281) 354-3699 • Fax: (281) 354-4475

|

|

Use on atmospheric pressure vessels

Adjustable pressure and level ranges

Electric pressure actuated switch for

controlling vapor pressure or liquid level controls

|

|

ChemValve

Model 330 Sleeved Plug Valve

Model 790 Lined Plug Valve

Model 880 Lined Plug Valve

Model 990 Lined Ball Valve

Butterfly Valves

Butterfly Valves

Check

& Gate Valves

Check

& Gate Valves

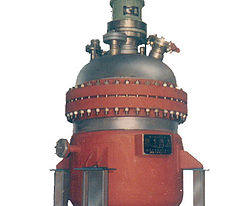

Side Entry Mixers

Side Entry Mixers

Top Entry Mixers

Top Entry Mixers

Specialty Applications - Bottom Entry, Rake Mixers, Etc

Specialty Applications - Bottom Entry, Rake Mixers, Etc

Static Mixers

Static Mixers

Portable Mixers

Portable Mixers

Magnetic Drive Mixers and MTC Series

Magnetic Drive Mixers and MTC Series

|